Graphite Electrode 6''-28'' Diameter for sale

Main Product Grades: NP, IP, HP, SHP, UHP

Normal Power Graphite Electrodes (NP)

Impregnation Power Graphite Electrodes (IP)

High Power Graphite Electrodes (HP)

Special Power Graphite Electrodes (SHP)

Ultra High Power Graphite Electrodes (UHP)

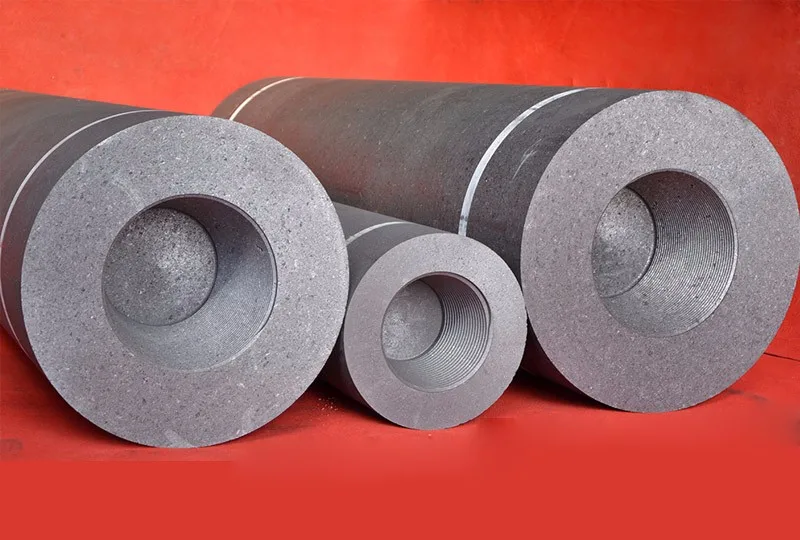

All graphite electrodes are offered with tapered nipples, i.e. 3 or 4 threads per inch, and meet the internationally accepted tolerances as per NEMA CG 1/ IEC 60239 / JIS R7201 standards.

Applications

Used in EAF and LF for steel making, as well as in electric smelting furnace for producing industrial silicon, phosphorus, etc.

Programmable properties

Good electrical conductivity

High resistance to thermal shock

High mechanical strength

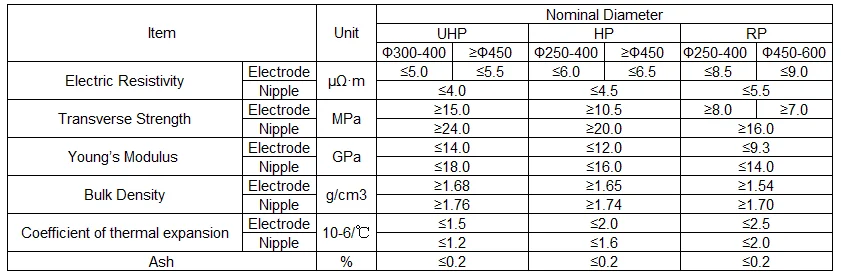

TECHNICAL PARAMETERS

Supply scope of graphite electrode( in diameter) :Φ150 (6 inches)- Φ700mm(24 inches); We can design tailor products as per the customer's actual operational parameters.

Specifications:

Packaging & Shipping

Packaging Details

Standard seaworthy packing or as customers' requirement. All wooden pallets are with fumigation.

Delivery Time

45 days after L/C operative OR full advance payment

Terms of Payment

China's most Dependable & Professional Graphite Electrode manufacturer.

CIMM Donghai is a top professional manufacturer of carbon product in China. Our main products are 200-700mm NP, HP, UHP Graphite Electrodes and Graphite Cathode Carbon Blocks. In the last decade our products were exported to more than 40 foreign countries and areas and got high reputation from our customers all over the world.

Technology and Innovation

In order to maintain our technological leadership and meet the technical requirements of the different types of furnaces( AC/DC, Ladle furnaces), we constantly invest in our production technologies. We have successfully produced large size UHP graphite electrodes with diameters from Dia.600 mm to Dia.700 MM, which filled gap in this field in domestic markets. With the characters of cost savings and good stable performances, our large size UHP graphite electrodes have replaced imported graphite electrodes in domestic market and accepted by overseas famous iron & steel plants gradually.

Manufacture & Supply Capacity

• High-Precision Auto Burden System

• 3500MT Extrusion Forming Machine

• Car Bottom Baking Furnace

• Ultra High Pressure Impregnation System

• Lengthwise Graphitization Furnace

• CNC Machining Centre

extrusion forming machine

Production Process Control

• Inspection of product appearance and dimension is made up of self-checking, next process cross-checking and quality inspection department supervising and checking.

• The production process index proceeds strictly as per production regulation and is controlled by PLC, meantime, PLC will feedback the process index situation to technical and quality inspection department for supervising, to guarantee the product quality.

Quality System Control

• Management delegates and quality inspection department organize internal examine every year to supervise and check system running status.

• Second party inspection is carried out by end user

• Third party inspection is carried out by certification authority

• Packing and logistic is farmed out to other company, and strictly execute as per Contract items.

• We have specific after-sales service teams to check our product performances, and feedback the problems to company for improving.

Global Sales & Service Network

Phone: 86-411-62885563

Fax: 86-411-62885581

Company Address:

2/F Zhiye Plaza 135-137 Guangxian Road, Dalian Hi-tech Zone, Liaoning 116023